8 companies with innovative upcycling solutions to transform waste into useful products

Up, this is the way

Our world generates more than 2 billion tonnes of municipal solid waste every year. That’s an average of 0.75 kg per person per day worldwide, with huge variations (from 0.11 to 4.54 kg) depending on countries (World Bank, 2018). Global waste is expected to grow to 3.40 billion tonnes by 2050.

A large part of this waste is not managed in an environmentally safe manner, and only a fraction is recycled. In the U.S., the country generating the biggest amount of waste, only 6% of plastics and 30% of glass bottles are recycled (World Economic Forum, 2022).

Solutions to this problem exist. Upcycling, defined as the process of reusing waste materials to create new items of higher quality or value than the original, is certainly one of them. All around the world, dozens of companies, of all sizes and from all industries, are inventing new ways to not only reduce waste but to create better products with it. Here are a few showing the way.

1. Rothy’s — Shoes from plastic bottles

American brand Rothy’s launched in 2016 in San Francisco and has since then opened a dozen of stores all over the U.S., along with its own factory in China.

All Rothy's products (a whole range of shoes for women, men, or kids, along with bags and accessories) are made from recycled plastic water bottles and other post-consumer materials. The process starts by hot washing and sterilizing the water bottles, then melting them down into pellets and stretching them into fibers. The uppers are knit with these fibers, and then hand-sewn to soles made from recycled foam and rubber, or algae-based foams.

So far, more than 146 million single-use plastic bottles have been turned into shoes and the company said it has “repurposed more than 493,000 pounds (224 tonnes) of ocean-bound marine plastic.”

Rothy’s also started an in-store recycling program in 2022 (consumers can bring back their used shoes and get a discount voucher), and intends “to close the loop and achieve the goal of fully circular production by 2023.”

2. Looptworks — Goods from excess textile materials

Founded in 2009 in the USA, Looptworks has the mission “to transform the world's excess textile materials into premium upcycled goods, recycled fibers and downcycled goods,” helping to eliminate global textile waste.

The company has released a line of 100% recycled and recyclable t-shirts and fleece sweatshirts, designed to be durable and last longer than traditional clothing. A takeback program to repair or recycle garments is also proposed. The production of these clothes uses 95% less water than traditional clothing.

Looptworks has developed partnerships with some of the world’s biggest brands, including Adidas, SHEIN, the NBA, and Southwest Airlines. In December 2022 a partnership with Cycle Dog was made to create a practical line of dog gear upcycled from excess materials and recycled bicycle tire tubes.

3. Bureo — Garments and accessories from discarded fishing nets

California-based Bureo is producing NetPlus, a material made from 100% post-consumer recycled fishing nets. The nets are collected, deconstructed, and re-formed into 100% recycled pellets, then extruded and spun into yarn.

The material is used to manufacture T-shirts or objects like “the first skateboard deck made from recycled fishing nets,” but is also included in the supply chain of several partner brands to produce various textiles and accessories, from hats or shirts by Patagonia, to sunglasses by Costa.

Working directly with fishing communities and ports, the company has already collected more than 3,300 tons (7.2 million lbs) of discarded fishing nets.

4. Alterpacks — Containers from spent grains

Spent grains (such as malt and barley) are grains that food manufacturers have used in their production cycle and then disposed of, going to a landfill or used as compost or animal feed. Singapore-based start-up Alterpacks upcycles these spent grains to create 100% organic food containers and cutlery.

All products are freezer and microwave friendly, and certified by the U.S. Food & Drug Administration and the Singapore Food Agency as safe for direct food contact.

5. Koushi — Protective helmets from scallops shells

In Japan, Koushi has developed a solution to upcycle scallop shells that would have otherwise been discarded as waste. The shells are finely crushed and sterilized before being transformed into protective helmets called Shellmets, stronger than standard plastic helmets and available in 5 colors.

Compared to using standard materials, the process reduces CO2 emissions by approximately 50%.

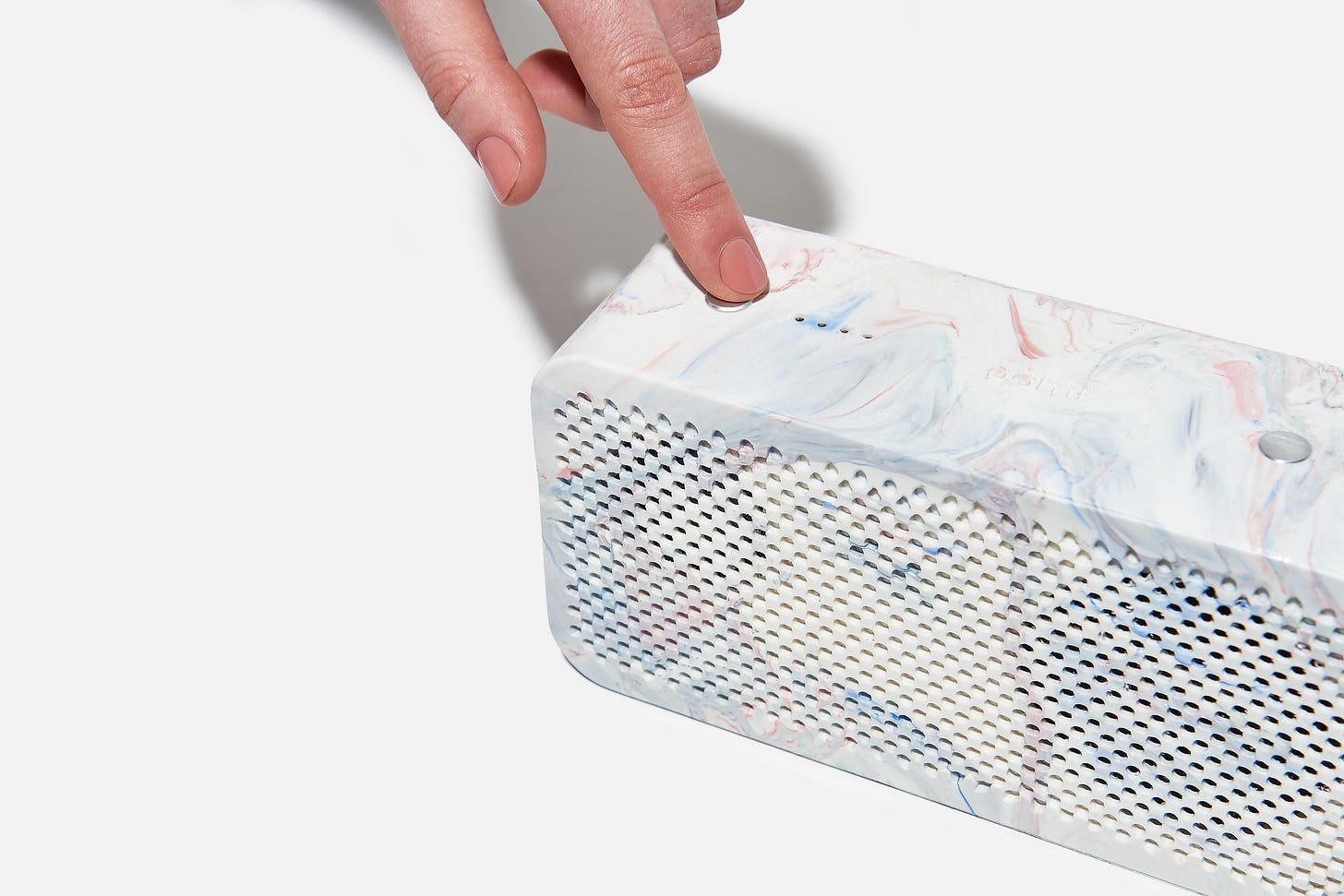

6. Gomi — Portable speakers from non-recyclable trash

British sustainable design studio Gomi uses only raw materials from waste streams that would otherwise be landfilled or incinerated, especially plastics and reclaimed battery cells, in order to create upcycled products.

Their flagship product is a fully functional portable speaker made from discarded components and second-hand battery cells from Lime’s e-bikes. The company also created other zero-waste products, such as portable or wireless chargers. Gomi’s new collection will drop in March 2023.

7. The new raw — Furniture from plastic waste

In Rotterdam, the Netherlands, designer studio The new raw is dedicated to “crafting plastic waste with robots.” In practice, the company has built dedicated large 3D printers that use filaments from plastic waste to shape original designs.

The process was used to create various pieces of sustainable and recyclable furniture: home furniture (chairs, sofas), street furniture (benches, elements for open-air playgrounds), or limited series for partner brands (beach fitting rooms and sunbeds made from upcycled marine plastic waste, for Coca-Cola in Greece).

8. Regen Fiber — Concrete from decommissioned wind turbine blades

Regen Fiber is a new U.S. business that has created a patent-pending, eco-friendly process to recycle decommissioned wind turbine blades into reusable materials for manufacturers in the concrete, mortar, and other industries. This process prevents the blades from ending up in landfills or releasing combustion byproducts into the atmosphere. The primary end-product is a top-performing reinforcement fiber that increases the tensile strength, toughness, freeze-thaw resistance, and durability of concrete and mortar applications.

The company is piloting the process at a facility in Des Moines, Iowa, and will begin commercial-scale operations in the second half of 2023 at a new manufacturing facility being built in the state. Regen Fiber is also already recycling new wind turbine blade manufacturing scrap materials at a commercial scale.

Worth mentioning too

Initially founded by two skippers with the intent to upcycle damaged sails and scrap parts from yachts, Ukraine-based start-up REwind has changed its course and is now producing garments from parachutes, in a dedicated collection named #Demilitarization. Created “to capture the reality of the war that is currently taking place in Ukraine,” all items, from hats to jackets, from ponchos to backpacks, are produced “from trophy parachutes ’S-4U’ used by the army of Russian occupiers.”

The bottom line

Upcycling works. It can even be considered as a kind of “contemporary alchemy,” transforming “trash” into “beauty”, or at least into products that are sometimes high-end, often desirable, and always sustainable. This is the very definition of creativity and innovation: solving an actual problem while improving over the starting point.

Whether crafted by hand or scaled up at the industrial level, upcycled products are here to say. And so is the logic of transforming pretty much any solid waste into something useful and better, making this world a greater place.